9 Best Practices to Boost Supplier Innovation

Rule # 1: Organize and Promote Monitoring to Effectively Engage Partners in the Innovation Ecosystem

Soliciting innovation from suppliers means first of all being able to communicate clearly on your strategic areas of innovation. It is above all not a question of restraining creativity, but of orienting the proposals towards the strategic priorities of the company (miniaturization, energy reduction, connectivity, CO2 reduction, etc.). The innovation plan or technological roadmap is a key tool for projecting and sharing this vision through multi-business governance.

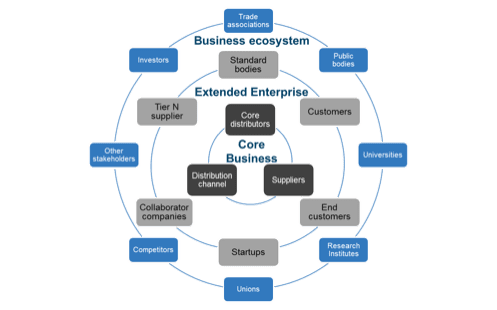

Then you need to properly map your innovation ecosystem. This is not limited to only suppliers but encompasses a more complete set of partners that it is a question of federating (suppliers, customers, universities, laboratories, start-ups, consumers, associations, etc.).

Finally, the areas of innovation can be promoted, shared and pooled with partners in the innovation ecosystem through different communication channels (strategic meetings, innovation portals, open innovation, forum, etc.).

In conclusion, capturing and succeeding in innovation depends first of all on an understanding and a clear organization of the relationship with its partners in order to make better use of the energies and skills of each.

Rule # 2: Identify and Select the Right Suppliers to Achieve the Right Innovations

Trop souvent les entreprises s’appuient sur un modèle classique de SRM (Supplier Relationship Management) pour identifier leurs fournisseurs privilégiés pour l’innovation. Ces modèles sont souvent guidés par une volonté de rationaliser le nombre de fournisseurs et conduisent à s’entourer de fournisseurs importants capables de répondre à l’ensemble des critères requis. Or les fournisseurs les plus gros ne sont pas forcément les plus pertinents pour l’innovation ! Réussir l’innovation c’est aussi s’entourer de fournisseurs plus petits, plus agiles, capables de vous accompagner dans les évolutions de votre Business Model (notamment guidé par la révolution digitale). L’intégration de ces « pépites » suppose de savoir adapter ses stratégies achats et notamment être capable de valoriser l’apport de ces fournisseurs afin de leur permettre de se développer avec vous.

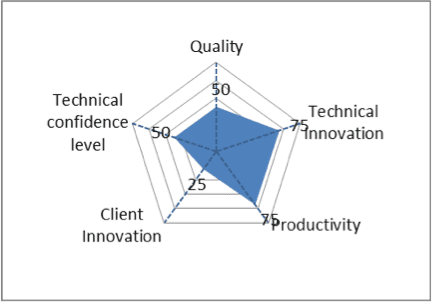

Nous avons retenu 3 critères majeurs pour identifier les bons partenaires :

- Skills: technological, quality, industrial, financial …

- The ability to cooperate: which is expressed in particular through strategic alignment and agreement on the main principles of collaboration and governance on innovation projects

- The “fit”: the compatibility of cultures but above all the desire and involvement of Top management

“Big is Beautiful” is not necessarily the panacea for choosing your co-innovation partners. Successful innovation is first and foremost a story of men and women and of cooperation between talents!

Rule # 3: Share the Right Information With Suppliers to Ensure Strategic Alignment

Encouraging supplier innovation and co-innovating is first and foremost knowing how to open up and not hesitate to share information deemed sensitive (hence the importance of rule n ° 2): exchange views on the market , consumer developments, sharing innovation plans, key elements of the technological roadmap, etc …!

Of course, it must be reciprocal. While spontaneous events can be organized (conventions, open innovation, etc.), it is important to organize strategic reviews with key suppliers (generally twice a year), in order to guarantee the involvement of top management and alignment of societies.

Innovation first emerges from exchange and must be driven by the Top Management of the 2 Parties

Rule # 4: Create a Climate of Trust to Co-generate Ideas With Partners

It’s well known. The majority of innovations come from the exchange and confrontation of ideas. There are many ways to organize this cogeneration: specific meetings, challenges, techdays, creativity sessions, collaborative platforms, etc. In all cases, it is important to agree in advance on a collaboration contract which sets the rules for collaboration and the exploitation of ideas (particularly in terms of intellectual protection, risk sharing, etc.).

How many attempts have been aborted or given birth in pain and frustration because the conditions for collaboration have not been clearly defined or started and especially carried by the governing bodies of the participating companies.

Creating a framework of trust with partners is a fundamental prerequisite for the success and sustainability of the cogeneration of ideas!

Rule # 5: Structure the Processing of Ideas to Select the Right Innovations

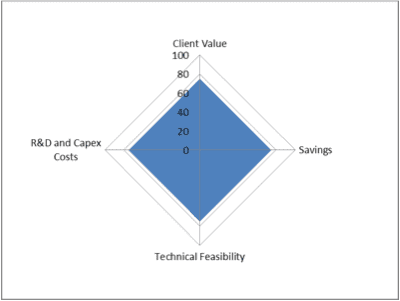

Generating ideas is not the most complicated. They should then be evaluated and easily discriminated against on the basis of rational criteria. This presupposes the establishment of standard documentation sheets in which the challenges (customer value, differentiation, competitiveness, etc.) and the level of risk (technological, industrial, etc.) are described in particular. A fluid process must make it possible to process ideas in a reactive way in order to give rapid feedback and argue with suppliers.

It is often good practice to do this 2-step evaluation (filter 1 and filter 2) which allows you to quickly rule out invalid ideas and focus on those of real interest.

Discriminate ideas with agility to achieve the right transformation and keep partners motivated!

Rule # 6: Promote and Structure Internal Exchanges to Better Manage Innovation

The establishment of multi-business governance (marketing, R&D, Purchasing, etc.) is a key success factor in organizing the promotion and management of innovation with suppliers or more broadly with ecosystem partners.

This governance is fundamental to aligning technological roadmaps, purchasing strategies and supplier roadmaps. Some companies are thus significantly changing their organizations. This leading automotive supplier, which has brought together part of its R&D and Purchasing / Supplier Development teams under the same organization (“Engineering Procurement”) to drive supplier innovation and ensure alignment with business roadmaps.

Multi-business internal governance is essential to effectively drive supplier innovation and align it with product strategy.

Rule # 7: Promote Internal Innovation to Create Envy

Fostering a culture of innovation requires the implementation of change management which is based on 3 axes:

- Create the right mindset: communications, celebration of success, recognition of the right to make mistakes, highlighting of suppliers, etc.

- Demystify: organize industrial / lab visits, share benchmarks, communicate on simple innovations made, etc. Innovation is within everyone’s reach!

- Give desire: create challenges or trophies, incentivize managers on the means dedicated to innovation, create a synthetic indicator, etc …

Innovation is above all a state of mind!

Rule # 8: Encourage Individual Involvement in Innovation to Increase Initiatives

Innovation cannot be decreed. It must be the initiative of everyone and of the greatest number. If communication and the promotion of innovation help to create this state of mind, that is not enough. It is also necessary to relay through managerial and HR actions.

- Empower managers: train and coach them to enable them to relay to the teams; allow them to devote time to innovation

- Integrate innovation criteria into the recruitment and evaluation processes, as well as into the integration pathways for newcomers.

Human Resources have a key role in spreading the culture of innovation!

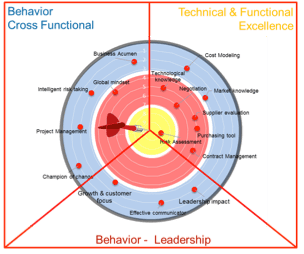

Rule # 9: Develop the Right Skills to Capture and Retain the Value Created

Successful innovation with suppliers also means knowing how to develop the right skills:

Develop technical skills: the classic mistake is to focus supplier innovation to fill a lack of internal technological skills! However, we must be able to always control the innovation coming from the supplier in order to capture the fair share of the value but also to keep it over time. Knowledge mapping is therefore an important prerequisite before embarking on such an approach.

Developing interpersonal skills: the skills required to generate and manage supplier innovation are no longer those traditionally expected of buyers. Technical or functional skills are replaced by leadership skills, Business Development, “Intelligent Risk Taker”, etc …

The time has come to replace the “Cost Killer” with the “Business Developer”!

Conclusion

To conclude, we will say that the success of supplier innovation depends on the organization of a structured ecosystem but sufficiently agile to bring out and achieve new opportunities. These new patterns of cooperation are both more complex and dynamic. They are shaking up the traditional modes of relationship between companies and their suppliers. Companies and in particular Purchasing must redeploy and equip themselves in order to face these new challenges. A major challenge to ensure the contribution of the purchasing function to the creation of value!