5 Key Questions Around the Logistics Network Design

1 / The Company Strategy

Many organizations question the relevance of their logistics plan and the proper organization of their flows. This reflection is all the more necessary as the large majority of distributors – nearly 80% according to our latest surveys – and a growing number of manufacturers, already engage in omni-channel.

Changes in the logistics network are often carried out under constraints, to compensate for storage area deficits, for example.

To be efficient, the flow master plan cannot be understood, link by link, but within the framework of a holistic vision.

The master plan, part of a medium / long term logic, aims to support the realization of the business plan of the company. It requires the involvement of top management with a view to a transversal reading of the issues and opportunities that present themselves to the company.

Changes in supply and demand must be integrated upstream in the various modeling scenarios, involving consideration of the rupture. For the most mature organizations, the Supply Chain master plan will even be accompanied by change management in other functions of the company, setting in motion a whole set of functions of the company.

In 2018, in France alone, more than 8 million m2 of additional storage area were put on the market. A phenomenon supported by a trend towards the regionalization of just-in-time flows.

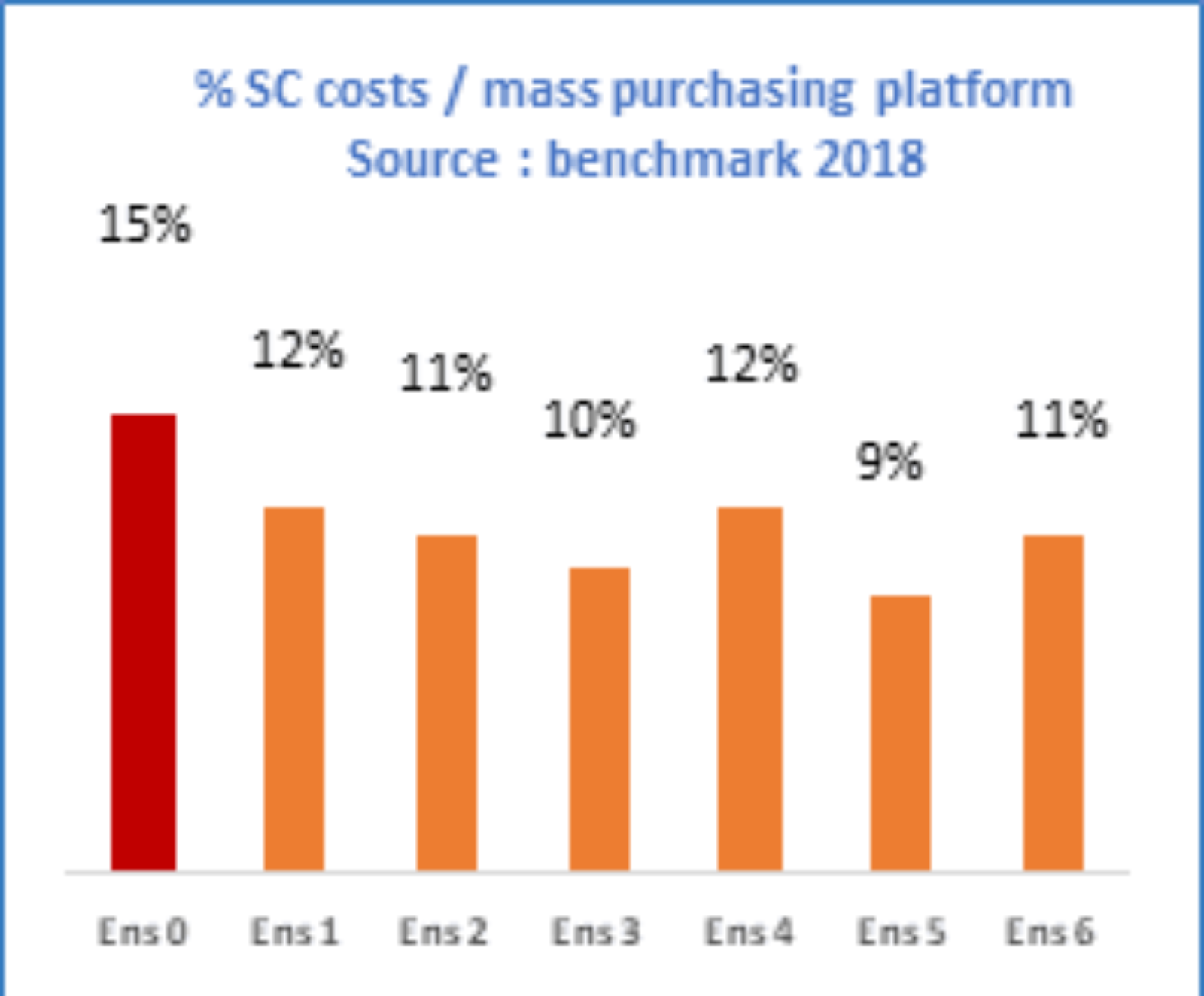

2 / The Supply-Chain Cost-VA Report

During a recent benchmark carried out with distribution players (a brand whose network in France represented at least 100 stores), the declared costs of Supply Chains fluctuate between 8 and 15% of total Purchases. Cost differences partly linked to the services offered by the various brands.

- Offering individual retail preparation to customers or internal customers, for example, requires an additional stripping operation, which increases picking costs by 2 to 3%.

- A promise of delivery on D + 1, allowing a craftsman to place his orders until 5 p.m. to be delivered the next day to his site before 7 a.m., is also an additional cost which must be precisely quantified in the field in order to allow decision-makers to decide whether or not to maintain it within the service offer.

Beware of the Misconception Which Would Consist in Thinking That Outsourcing Logistics is the Solution to Optimize the Cost / Service Ratio.

- This approach will certainly have the advantage of increasing the organization’s business expertise and offering flexibility. It can turn out to be disappointing, however. The markup operated by service providers represents on average between 5 and 15% increase compared to internal exploitation.

- If the products handled have strong specificities in terms of size or fragility, it may be all the more difficult to transfer know-how from your logistics teams to service providers.

3 / The Just-Necessary in Terms of Services

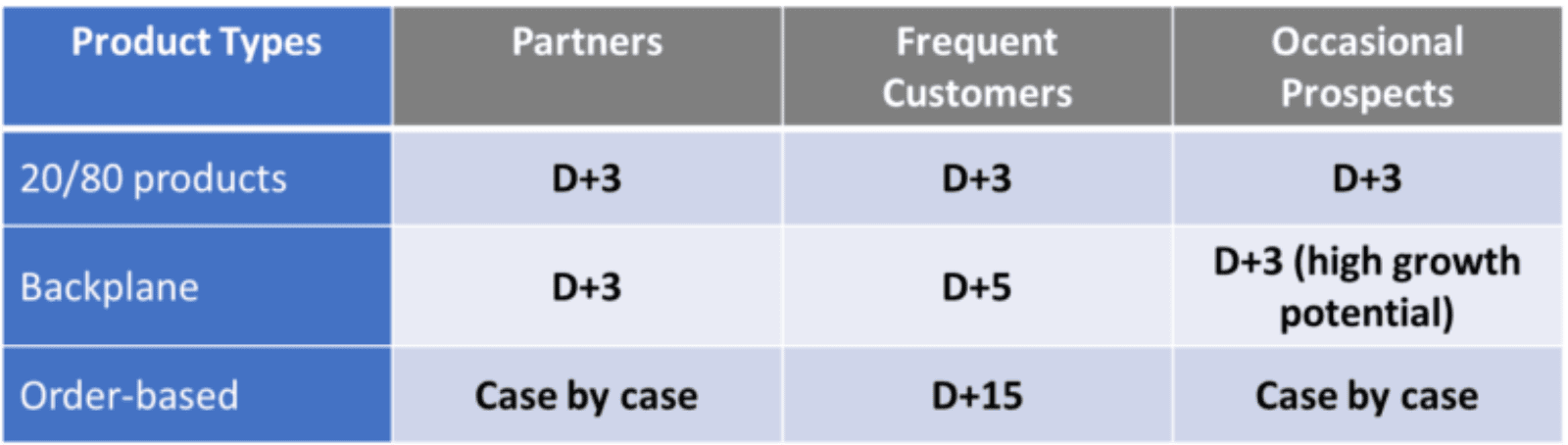

Once the operational costs have been read, the organization has the elements that allow it to define the right level of service to offer. A linear improvement in delivery times can be very costly. Is the effort made up to the real expectations of customers?

In addition to reading by type of product, the reflection can focus on segmenting customers according to their attractiveness. This attractiveness can be evaluated according to the level of margin or growth of the market in question or even according to the potential for increasing the turnover of this client.

The definition of the customer promise requires a very good knowledge of the market. We can cite as an example this case where, requested by a cosmetic subcontractor seeking to reduce its lead-time from 14 to 10 weeks, collaborative workshops enabled us to demonstrate that the current deadline was perfectly acceptable to clients. On the other hand, the latter were uncompromising on the respect of this commitment. We have therefore reworked the organization of flows in order to secure this deadline, without exerting additional constraints on the flow diagram.

4 / Network risks

In the different scenarios that are modeled, a robust sensitivity analysis can be performed in order to verify the impact of the assumptions on the results, costs, quality and deadlines.

Whether indirect - with a 60% increase in litigation cases to be dealt with - or direct - with the application of penalties in more than 1 in 2 cases - poor anticipation of risks leads to very substantial additional costs!

They can even lead to the loss of customers in 30% of cases. Certain risks are relatively well understood by manufacturers, such as supplier risk which now appears almost systematically in model evaluation grids, or even country risks which gives rise, by the American property and casualty insurance company FM Global, to a recognized and shared world ranking

Other parameters, on the other hand, are much more difficult to model because they are often unknown.

First and foremost, there is regulatory risk. For example, changes in customs taxation represent a very disturbing factor in Supply Chains in our paradigm of a globalized economy. Closer and more concrete, the threat of taxation hanging over refrigerated transport is posed like a sword of Damocles on logistics flow patterns with costs per km that could go up to triple.

The multi-criteria analyzes and the workshops conducted as part of the master plan study make it possible to select the scenario that will maximize the benefits while limiting the risks as much as possible. The most resilient organizations work on the basis of “what if” scenarios in order to build a business continuity plan and secure the implementation of rapid backups.

5 / The Impacts of a Transition to a New Flow Pattern

A transition plan is usually set for a period of 2 to 3 years. This is the time needed to allow all actors in the value chain to adapt their business to this new pattern. It is essential that the identified projects involve the entire organization, the success of the project not being the sole responsibility of the Supply Chain. The crucial role of IS in these projects is obvious and requires the right level of technical skills (internal or external).

- One of the key success factors during the evolution of the master plan lies in the proper assessment of the necessary resources and an agile management of the potential bottlenecks that threaten the project. The savings and benefits schedule will thus be systematically linked to a resources plan in order to have a realistic reading of the P&L impacts in the short and medium term

- The entire organization and partners must be aligned with the target flow diagram which will allow either to embed the organization in a new dynamic, or in the event of failure to accelerate its decline. The priorities and the phasing of the projects are an integral part of the master plan.

- All manufacturers agree on the fact that one of the keys to the success of a large-scale project is to share responsibility with all the employees affected, whether they are Supply Chain operational staff, marketing, purchasing or even financial functions.

- Everyone must be convinced of the approach to carry the project internally but also to customers. Indeed, with the digitization of the act of consumer purchasing, there is no doubt that the Supply Chain master plan is more than ever a differentiating strategic element for the company.

Precautions Prior to Defining an Optimal Flow Diagram

Many Network Design solutions exist to support strategic thinking. But the temptation to take the shortcut of thinking this is the tool that will give the answers must be fought. The use of such solutions is often limited by the level and granulometry of the accessible data.

Nothing can replace collaborative workshops between professions for a relevant analysis and a fair appropriation of the approach. This is a prerequisite for any optimization process for the Logistics Master Plan.