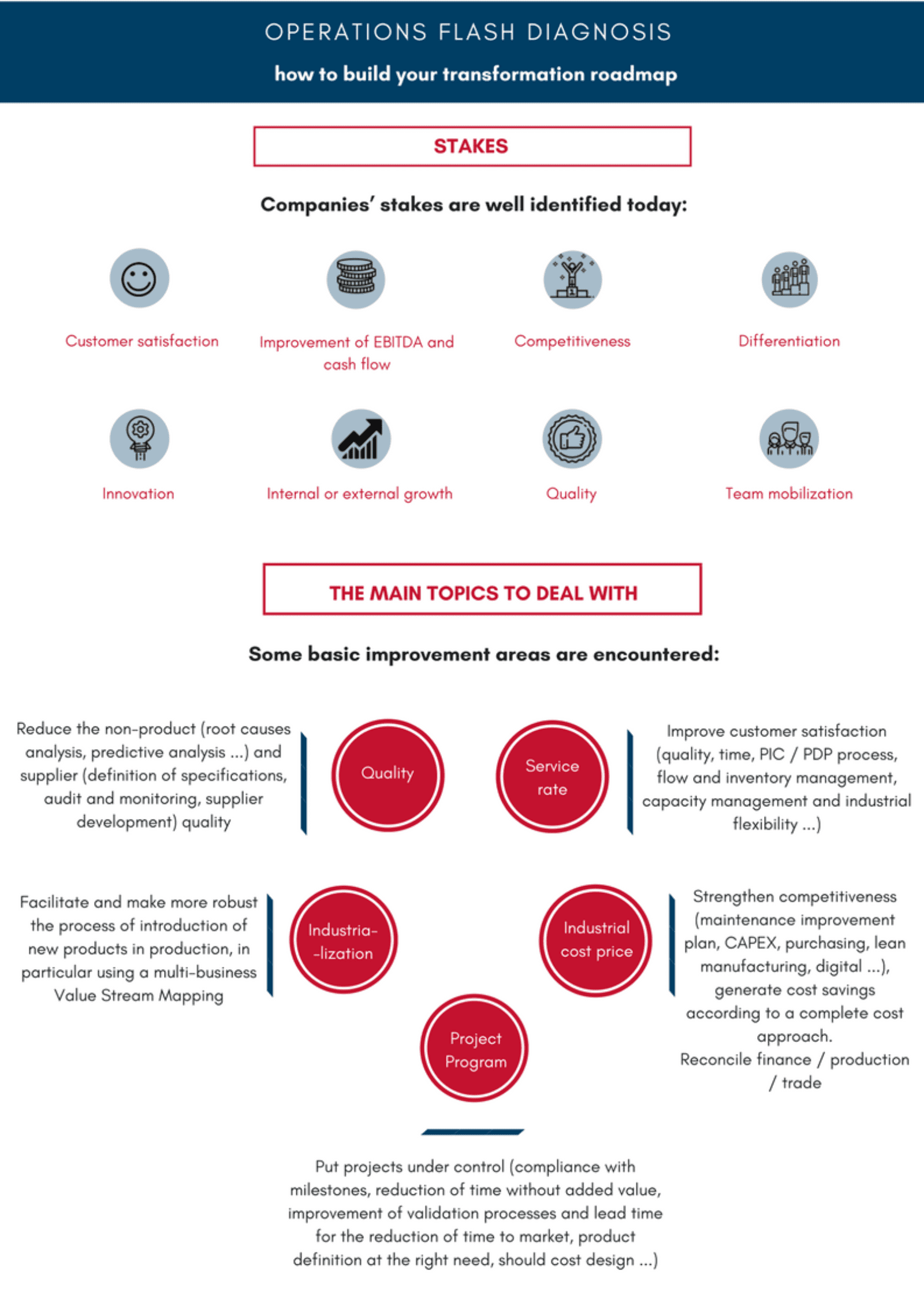

Flash Operations Diagnosis or How to Build a Transformation Roadmap

Reminder of the Major Business Challenges

The Major Issues Affecting Operations Today Can be Summarized As Follows:

- Customer satisfaction

- Improved EBITDA and cash flow

- Competitiveness

- Differentiation

- Innovation

- Quality

- Internal or external growth,

- Mobilization of the team.

The Main Areas for Improvement to Meet These Challenges

Service Rate

Improve customer satisfaction (quality, time, PIC / PDP process, flow and stock management, capacity management and industrial flexibility …)

Quality

Reduce product non-quality – root cause analysis, predictive analysis – and supplier – specification definition, audit and monitoring, supplier development.

Industrial Cost Price

Strengthen competitiveness – maintenance improvement plan, CAPEX, purchasing, lean manufacturing, digital … – and generate cost savings by reconciling finance, production and trade.

Industrialization

Streamline and make more robust the process of introducing new products, in particular using multi-business Value Stream Mapping (VSM).

Project / Program

Control projects: meeting milestones, reducing time without added value, improving validation processes and time-to-market, defining the product as needed, designing at target cost.

Among the Responses Offered by KEPLER to These Different Challenges: Flash Operations Diagnosis

KEPLER, with its many operational experiences in the industry, from innovation, to purchasing, through the supply chain and operations, provides concrete, practical, accessible, robust and pragmatic solutions around best practices tested and its benchmarks.

An Ecosystem of Digital Partners

KEPLER relies on its ecosystem of partners and digital solutions to help its customers build a precise roadmap with simple Proof of Concept (POC) to validate these new solutions.

Among the subjects addressed:

- Artificial intelligence

- Connected objects

- Real time monitoring

- Machine learning

- Predictive analytics

- Dematerialization

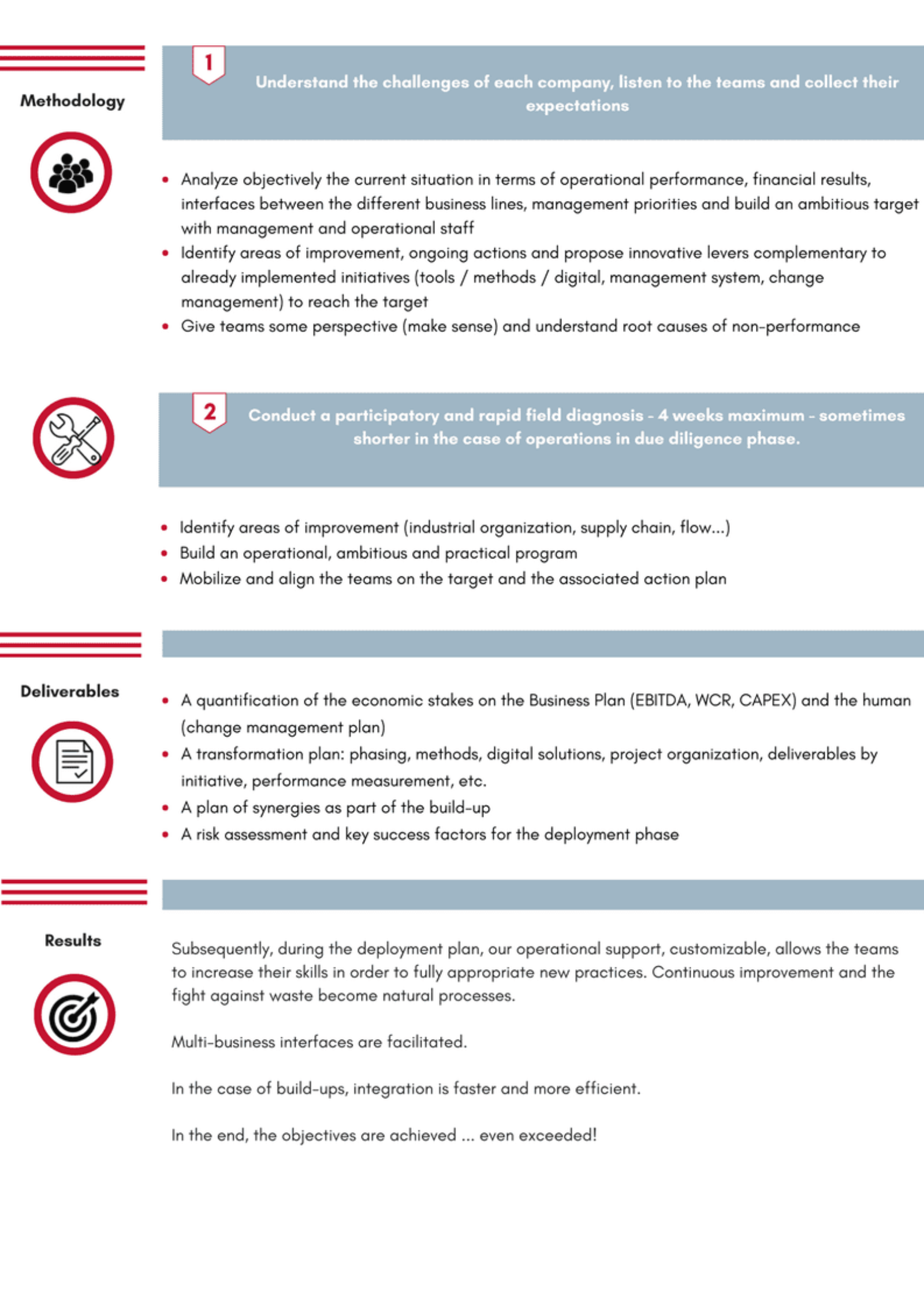

Methodology for a Flash Diagnosis

Step 1: Understand the Challenges of Each Company, Listen to the Teams and Collect Their Expectations

- Objectively analyze the current situation in terms of operational performance, financial results, interfaces between different business sectors, management priorities and build an ambitious goal with management and operational staff

- Identify areas for improvement, current actions and propose innovative levers complementary to initiatives already implemented (tools / methods / digital, management system, management) to achieve the objective

- Giving teams a (logical) perspective and understanding the root causes of non-performance

Step 2: Perform a Rapid, Participatory Field Diagnosis in 4 Weeks Maximum, Sometimes Shorter in the Case of Operational Due Diligence.

- Identify areas for improvement (industrial organization, supply chain, throughput …)

- Build an operational, ambitious and pragmatic program

- Mobilize and align teams on the target and the associated action plan

The deliverables of a Flash Operations Diagnostic

The 4 Components of the Finalized Flash Operations Diagnosis

Costing of the economic issues of the Business Plan (EBITDA, WCR, CAPEX) and human (change management plan).

A transformation plan including:

- Phasing,

- Methods,

- Digital solutions,

- Project organization,

- Deliverables by initiatives,

- Performance measurement.

Plan synergies within the framework of accumulation.

An assessment of the risks and key success factors for the deployment phase.

Expected Results of a Flash Operations Diagnostic

During the deployment plan, our operational support allows teams to increase their skills in order to fully take on new practices.

Continuous improvement and the fight against waste become natural processes.

- Multi-company interfaces are becoming more fluid.

- In the case of accumulations, integration is faster and more efficient.

In the end, the goals are met … and even exceeded!

Infographics